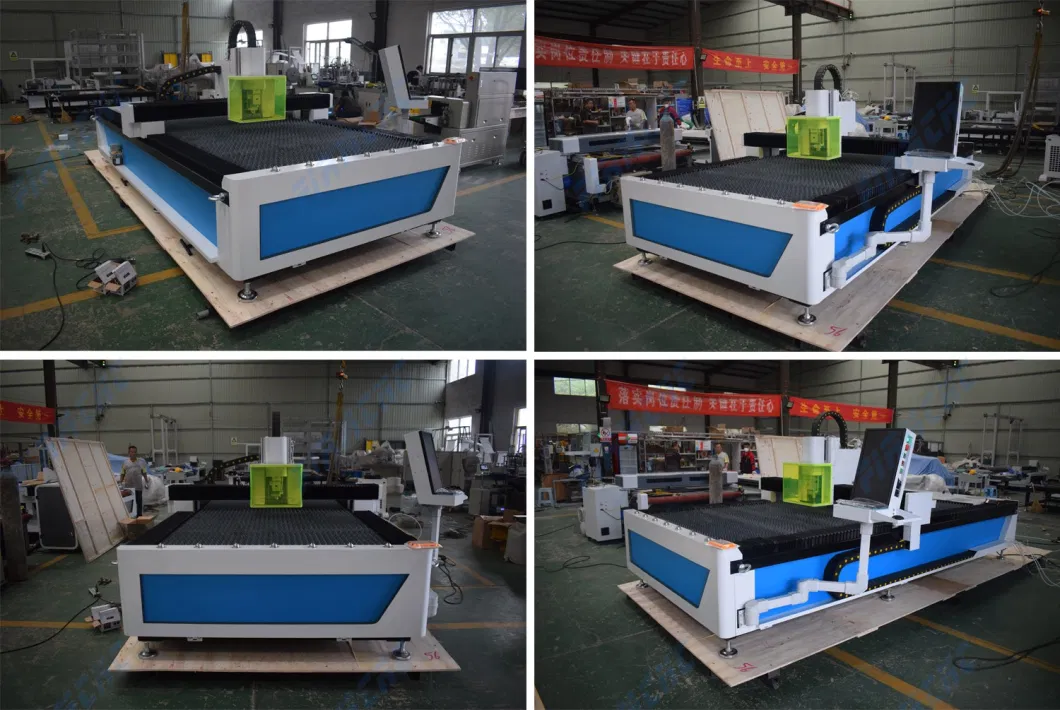

Hot Selling CNC Metal Fiber Laser Cutting Engraving Cutter with 1kw 2kw 3000W 6000W Stainless Steel Aluminum Mild Steel Sheet/Plate/Pipe/Tube Exchange Table

Description

Basic Info.

| Model NO. | FMJ1530 |

| Structure Type | Gantry Type |

| Laser Classification | Reci / Max / Raycus / Ipg |

| Laser Technology | Laser Control Fault Cutting |

| Motor | Yaskawa/ Panasonic /FUJI |

| Laser Cutter Head | Raytools / Lasermech (Optional) |

| Cutting Speed | 20m/Min--- 60m/Min |

| Auxiliary Gas | Oxygen, Nitrogen, Air |

| Gudie Rail | Hiwin / PMI (Optional) |

| Fiber Generator | Reci / Max / Raycus / Ipg |

| Reducer | Motovario / Shimpo |

| Fiber Power | 1000W-6000W |

| Control System | Shanghai Cypcut Controller |

| Transport Package | Standard Export Plywood Package |

| Specification | 3000*1500mm |

| Trademark | FIRMCNC |

| Origin | Jinan Shandong China |

| HS Code | 8456100090 |

| Production Capacity | 100 Sets/Month |

Product Description

Hot selling CNC Metal Fiber Laser Cutting Engraving Cutter with 1kw 2kw 3000W 6000W Stainless Steel Aluminum Mild Steel Sheet/Plate/Pipe/Tube Exchange TableProduct DescriptionFiber Laser Cutting Machine main features:

# Support the power range from 1000W 1500W 2000W 3000W ,up to 15kw .# Laser generator can be selected,you can choose RAYCUS, IPG,MAX,JPT,NLIGHT ect.# Laser Cutting head can support RAYTOOLS,AU3TECH,WSX,PRECITEC.# Reducer you can choose XINBAO ,MOTOVARIO# Servo motor and driver you can choose FUJI/YASKAWA# Working area you can choose 3015,4015,4020,6025,8025 or other optional.Support customization ,you can choose :1.COVER , more environmentally friendly and easy to clean2.ROTARY for tube/pipe cutting ,multifunctional cutting3.EXCHANGE TABLE ,double platform working , improve production efficiency

Techncial specification:

| Fiber Laser Cutting Machine Technical Parameters | |

| Laser Type | Fiber laser |

| Laser Brand | IPG / Raycus / MAX / RECI |

| Laser Power | 1000W / 2000W / 3000W |

| Working area | 1300mmX900mm / 1300mmX2500mm 1500mmX3000mm / 2000mmX4000mm / |

| 2000mmmX6000mm | |

| Working Table | Fixed Working Table / Pallet Changer |

| Control System | PMAC full-closed loop servo control |

| Driving Mode | Double ball screw driving / Double gear rack driving |

| Idle/Processing Speed | 120m/min / 60m/min |

| Positioning Accuracy | 0.05mm |

| Protection System | Enclosure protection |

| Laser Head | Precitec / Raytools |

| Power Supply | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

| Total Power | 6KW~20KW |

| Floor Space | 5.6mX3.2m (fixed table) / 6mX4.6m (shuttle working table) |

| / 8.5mX4.2m (pallet changer) | |

| Standard Collocation | Metal nesting software, dual-pressure gas route of 3 kind gas sources, |

| dynamic focus, remote controller, etc. | |

| Auxiliary System | |

| Cooling System | Dual temperature dual control water chiller |

| with purification system | |

| Lubrication System | Automatic lubrication |

| Laser cooling system | Horizontal air conditioning |

| Auxiliary gas system | dual-pressure gas route of 3 kind gas sources |

| Laser cutting head | Dynamic focus |

| Circuit and protection system | Independent work station |

| Software System | |

| Software | Shanghai Cypcut |

| Supported Format | PLT, DXF, BMP, AI, DST, DWG, etc. |

D : Advantages of our fiber laser cutting machine:1 Fast speed:80m/min, two driver, synchronous high speed move;2 Leapfrog cutting:Improve the cutting speed, processing efficiency and accuracy; 3 Scan cutting :Short distance cutting without head lifting, 4 Cutting and marking functions:Power can be controlled set with two layers, one cut and another mark, you can cut and mark together on one metal part;5 Automatic search edge function:If metal sheet put slanting , machine can auto detect, and auto adjust cutting, less waste and no need to replace material;6 Power off cutting memory:When suddenly power off, software has memory of cut stop point, after power on, you can start cutting from the break point; 7 Install Proportional Valve:Use software to change the air and control the air pressure automatically, no need to change the air manually, it can save you much time; 8 Stable working table:Use 16mm thick steel side board, around 5 tons in weight;Dual drive, aging treatment, stress relief test to ensure long time fast running without changing shape; 9 Air condition for control cabinetcooling for Electronic parts and Laser Power Supply, make sure control cabinet temperature at 26ºC,extend the life of electronic devices and save the power for the factory.10 High electrical-optical conversion efficiencyFiber laser can convert up to 30 % electrical energy into laser energy. High energy conversion makes fiber laser more energy efficient.

Applicable materials for fiber laser cutting machineFiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.Application IndustriesFiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Jinan FIRMCNC Equipment Co.,Ltd is situated in Jinan city, Shandong province, we have devoted to cnc router industry more than 18 years,with strong technical strength and perfect service network in industrial,it provides one-stop solution of cnc wood router processing equipments,services and customized application for different requirements.our machines obtained humanity design,advanced technology, rich cnc router solutions,better users experience and European standard etc.

Our products including cnc wood router, wood lathe, wood cutting machine, cnc lathe, mould cnc milling machine, fiber laser cutting machine, co2 laser machine, laser marking marking machine, plasma cutting machine, edge banding machine, sliding saw table etc.Besides, we have 10 modern production and processing workshops, our 2 R&D teams,2 after-sale service teams.our machine are most popularamong multi industries, and clients covering almost all the Countries who doing importing and exporting business.

Save space as much as possible for container loading.Inside: Water-proof Plastic Film Package With Foam ProtectionOutside: Solid Seaworthy Wood Box PackageBelow: Steel Tube

1) Foam and wrapping film on the surface of the machine inside. Rain-proof, Dust proof.2) Standard export plywood case. Upwards, moistureproof shipping marks. Safety guaranteed.3) Fumigation-free4) With shipping mark if you like.5) Outside: Marked packing size, model, weight and other information

Q1.Can you recommend a fiber laser cutting machine to me ?

Yes, In order to give you a suitable fiber laser cutting machine,pls tell me your working area ? processing materials ?

Then perfect suitable machine will be recommend.

Q2.Do you have operation manual and working video?

Yes,we will send it together with machine.

Q3.Does your company can processing my samples?

Yes, we can.

Q4.If I bought machine, but don't know how to operation, what I can do?

Our engineer will teach you how to operation the machine through manual, video call or email, I still aso will help you .

Q5.How am I going to work on service parts on the machine? Example what if parts need to be replaced?

During the period of warranty, we will free send broken parts to you, after warranty, we can offer agent price for parts.

usually for all parts can perfect working one year without any broken .

Q6.Does your engineer do aftersale service at abroad? how much cost?

Yes, our technician can do training and after sale service at yoru factory, you only need to pay the round air tickets cost and accommodation for technician.

Our Contact